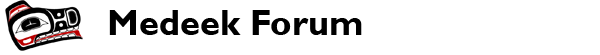

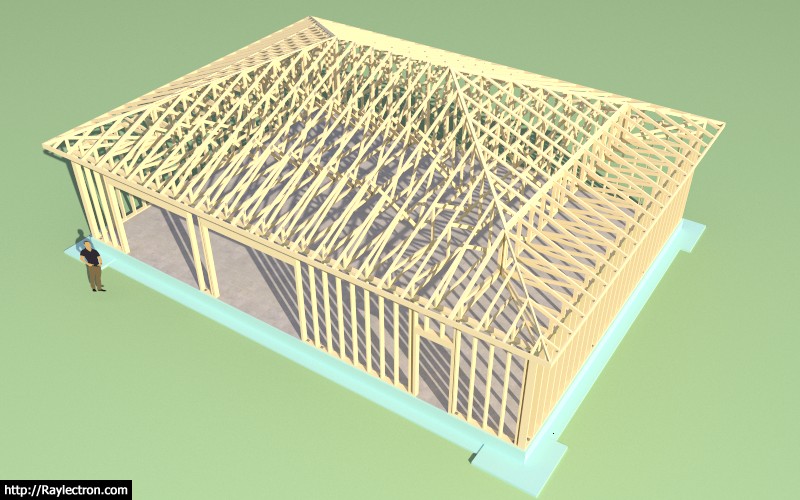

Added energy/raised heels for stepdown hip set (3 variants: wedge, slider and vertical w/ strut).

View model here:

https://3dwarehouse.sketchup.com/model/5e38b8eb-5c4d-4e05-a48e-63ceee60652b/Commercial-Building-with-Hip-Roof

Now the possibilities are limitless since you can match the heel height of any other roof (ie. rafter, TJI etc...)

Adding in this feature was not as bad I thought it would be but each truss type in the set must be considered and dealt with separately:

- Common Trusses

- Hip Trusses

- End Jacks

- Hip Jacks

- Corner Jacks

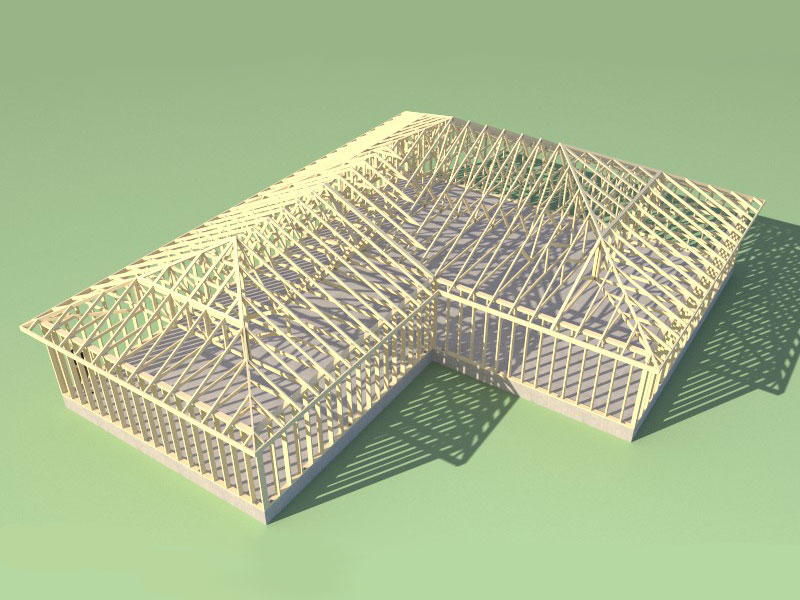

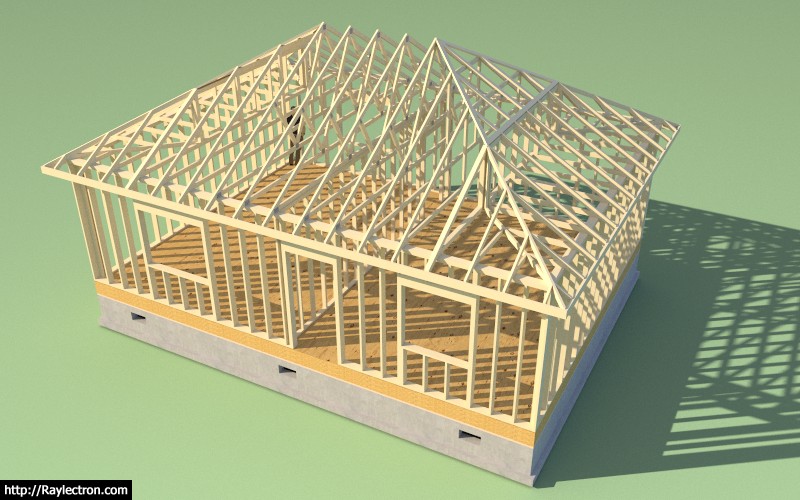

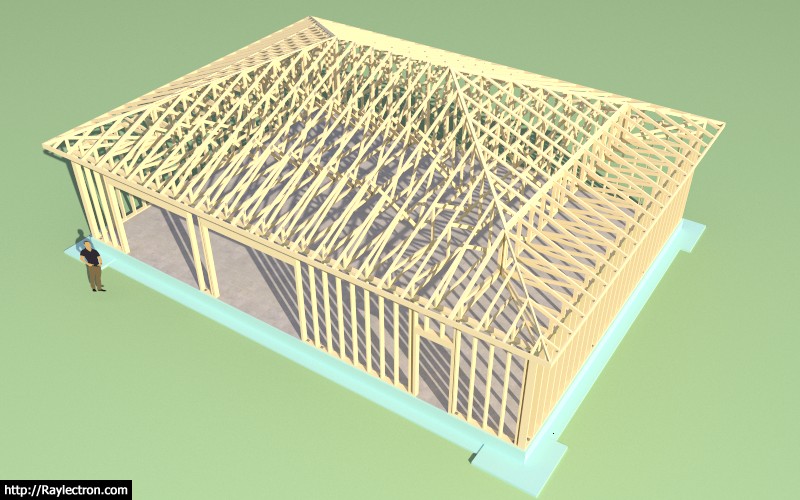

View model here:

https://3dwarehouse.sketchup.com/model/5e38b8eb-5c4d-4e05-a48e-63ceee60652b/Commercial-Building-with-Hip-Roof

Now the possibilities are limitless since you can match the heel height of any other roof (ie. rafter, TJI etc...)

Adding in this feature was not as bad I thought it would be but each truss type in the set must be considered and dealt with separately:

- Common Trusses

- Hip Trusses

- End Jacks

- Hip Jacks

- Corner Jacks