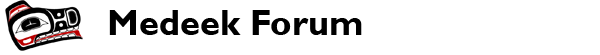

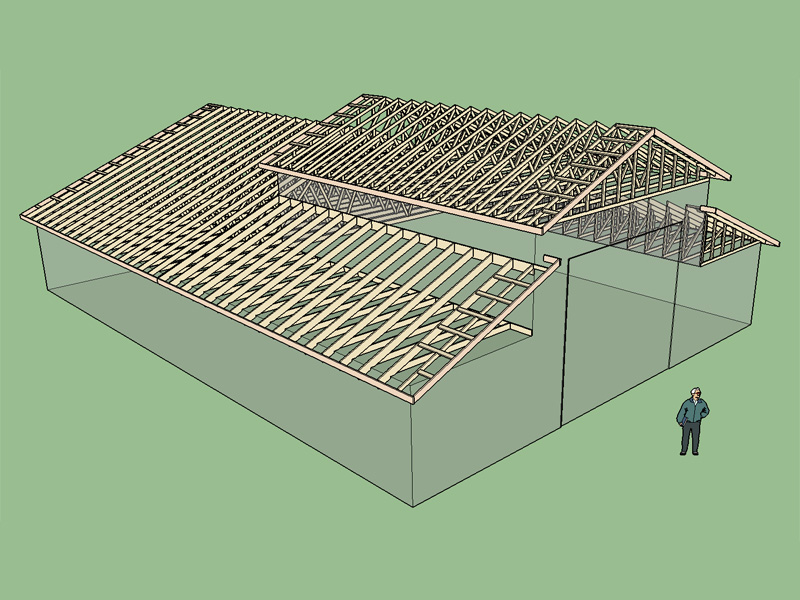

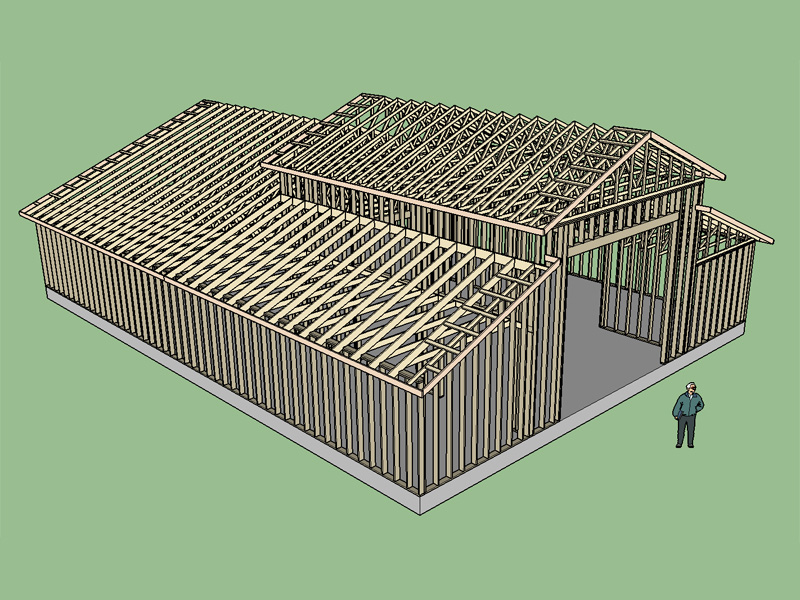

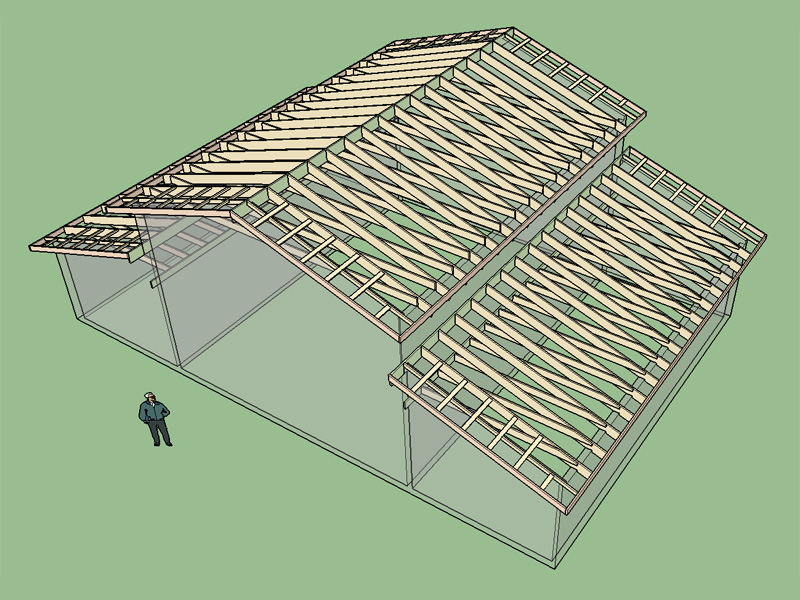

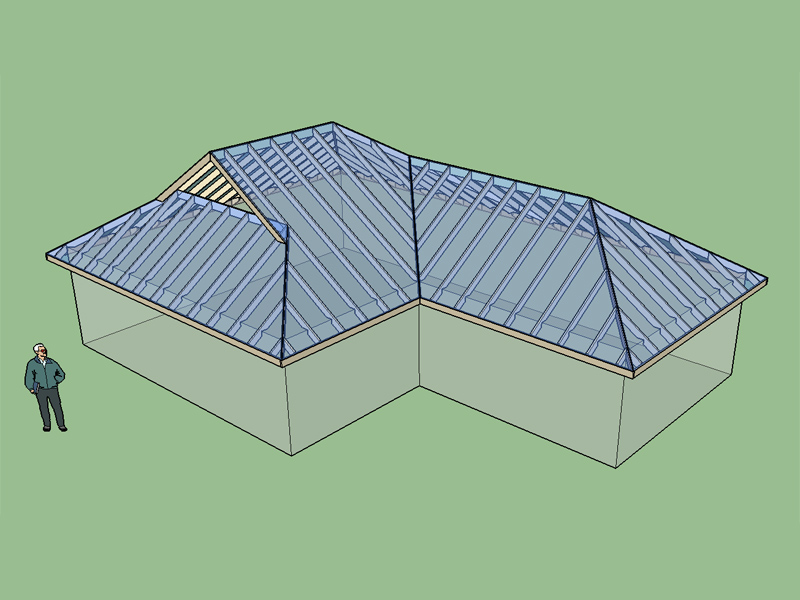

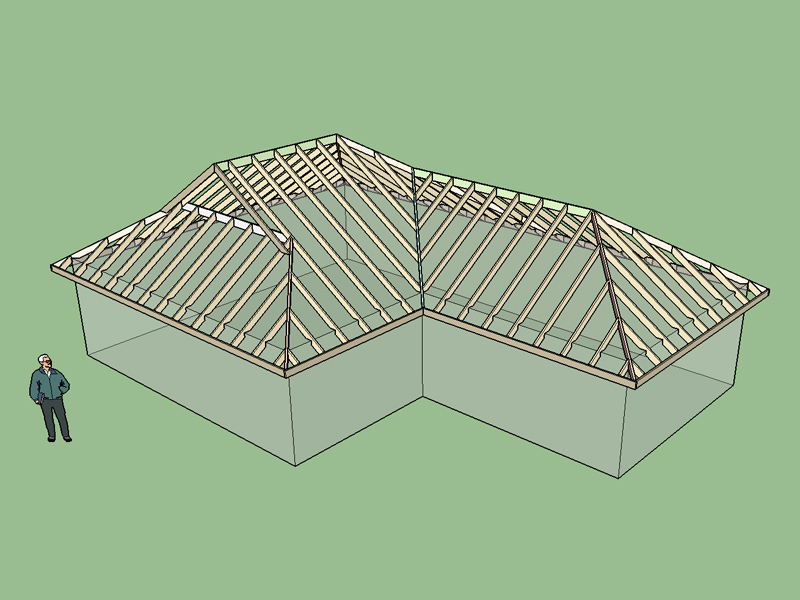

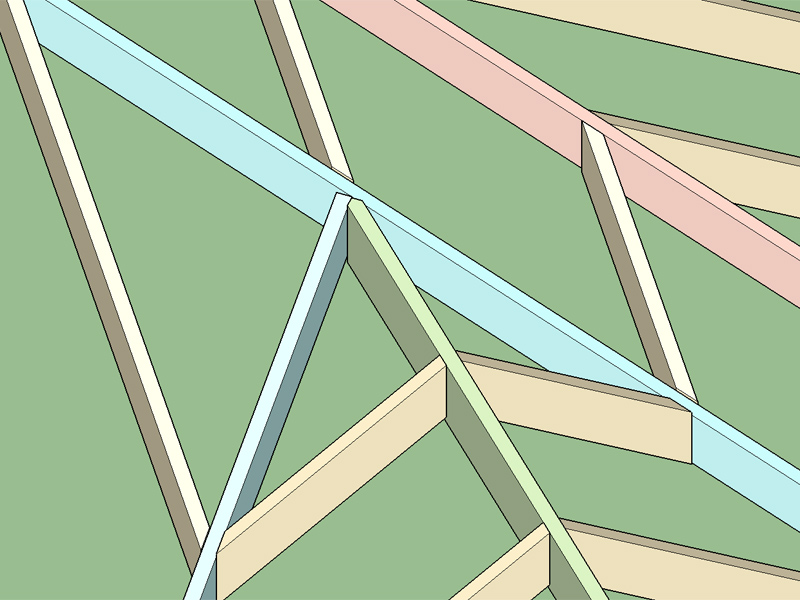

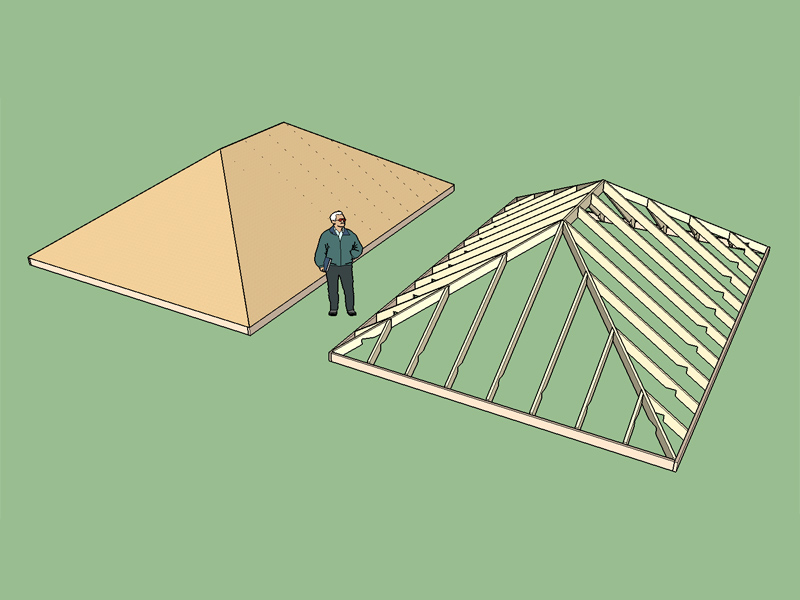

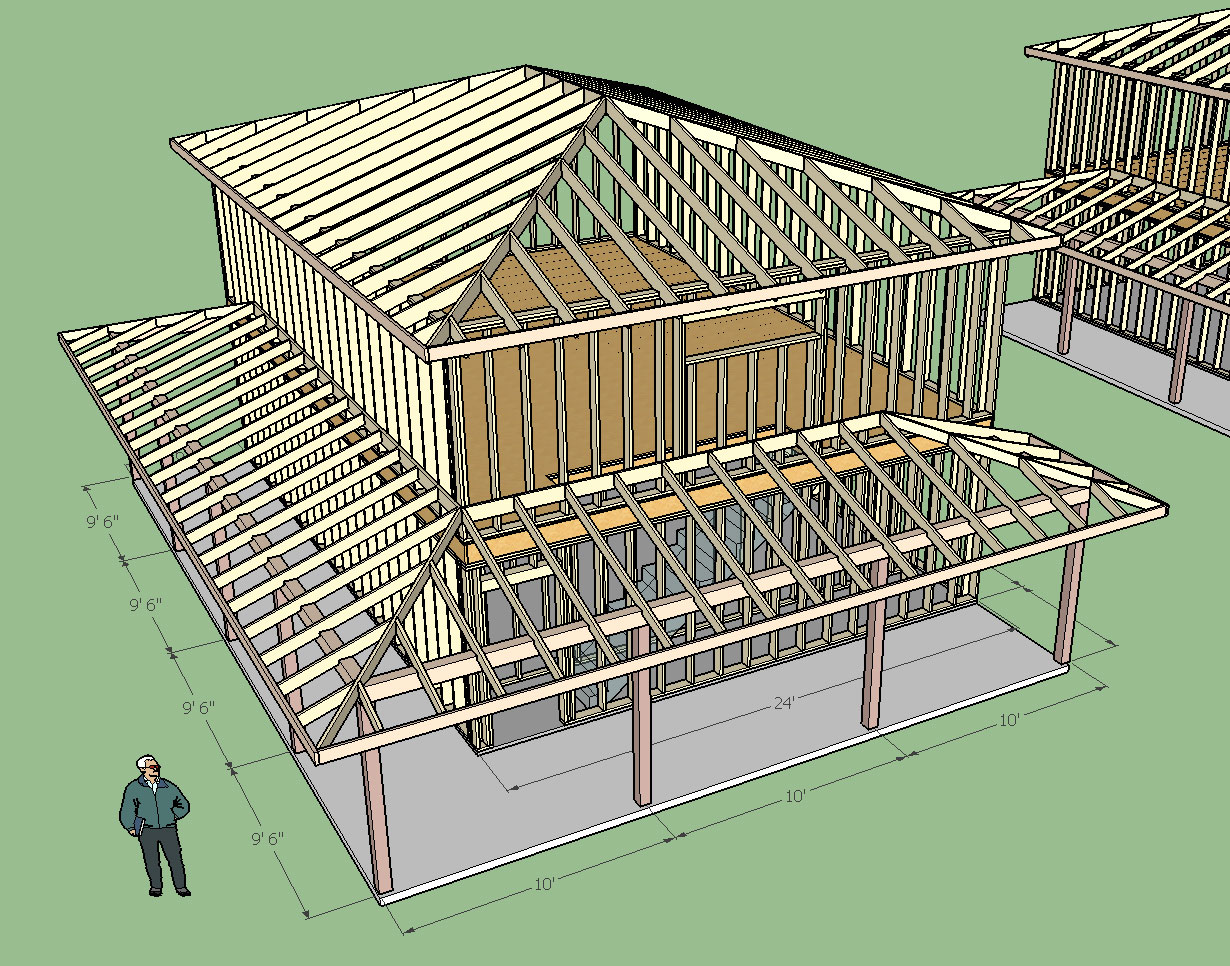

I added the porch roof using the hip roof and shed roof primitives. I'm wondering if it might not be worthwhile to add in a feature to create this type of combination roof automatically. Shed Roof w/ ledger & hip ends.

View updated model here:

https://3dwarehouse.sketchup.com/model.html?id=uf979b67e-2755-4981-9bfc-06d20b64d313

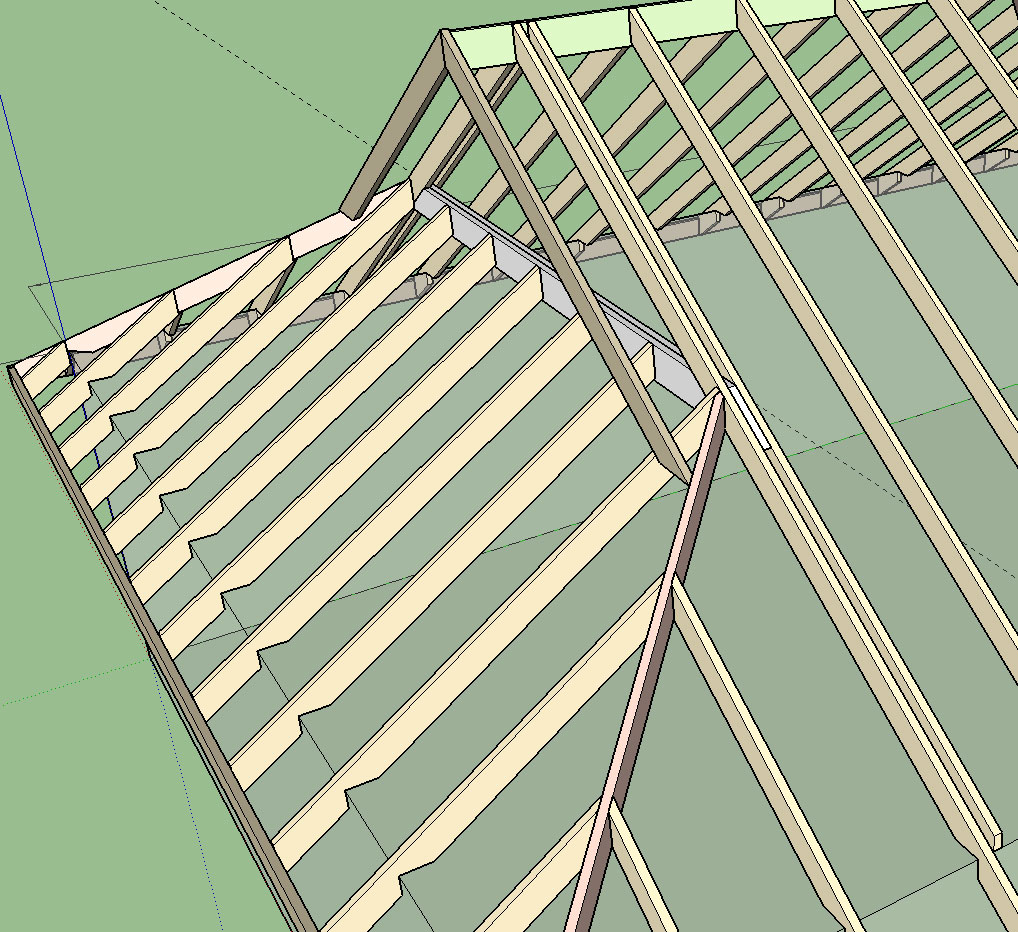

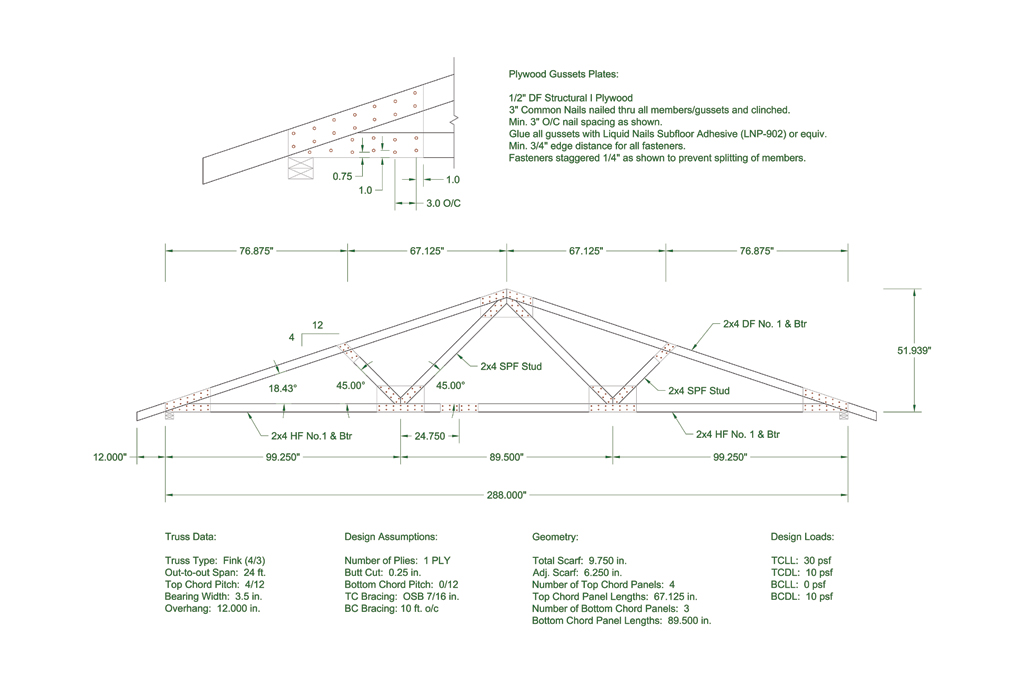

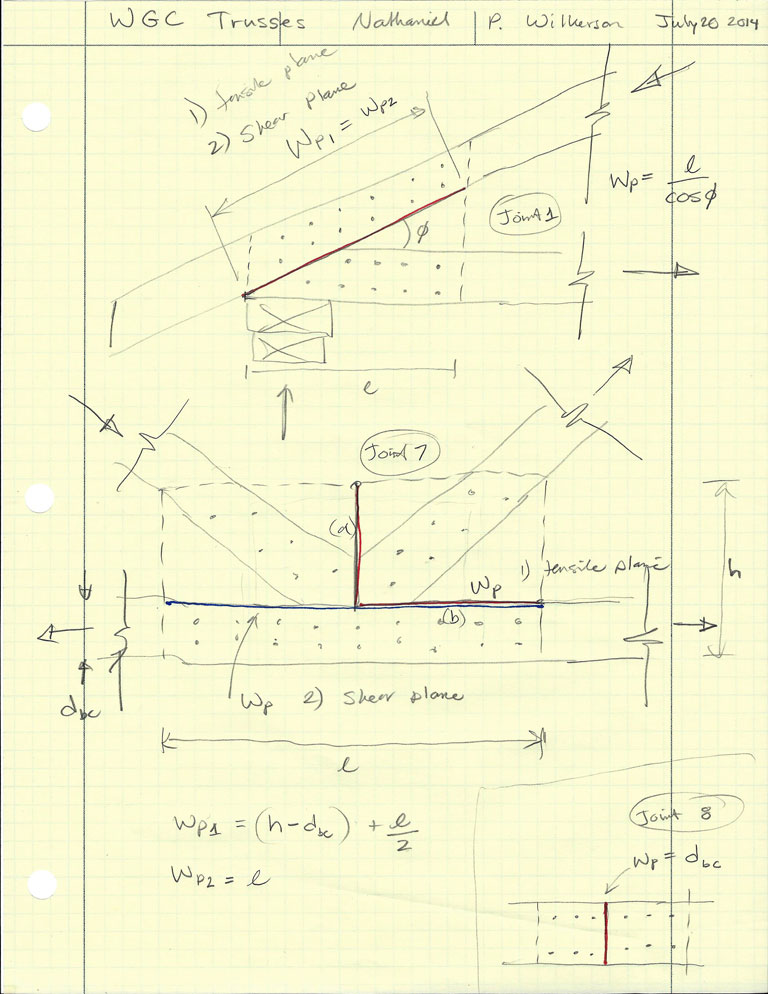

Note, how close the ledger is to the rim joist. The porch roof diaphragm will actually stiffen up the region of the wall where the stairway is to some extent, in general the use of a "wind beam" is probably advisable if platform framing is used and a quick check of the numbers should be done.