Version 1.7.7 - 12.31.2016

- Enabled materials and custom layers for gable, hip, shed, TJI and dutch gable rafter roofs.

- Enabled materials and custom layers for gable, hip, shed, TJI and dutch gable rafter roofs.

SMF - Just Installed!

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Show posts Menu

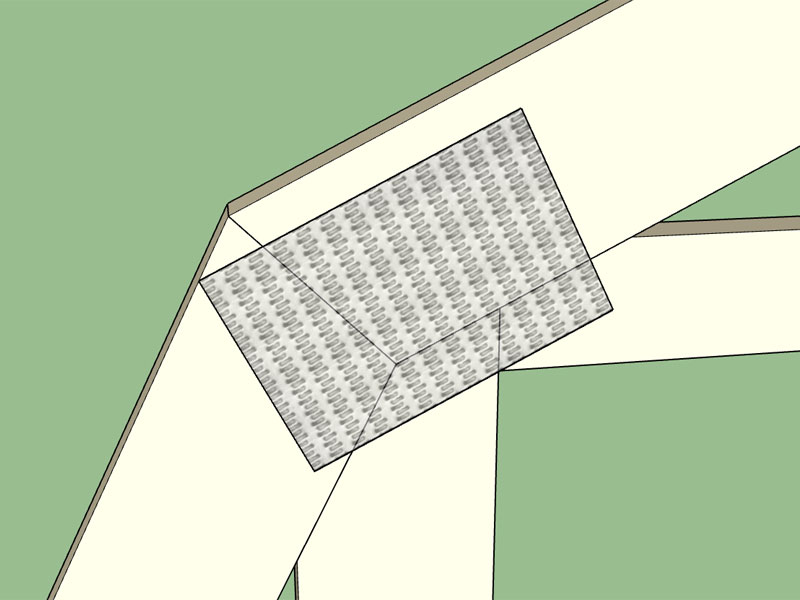

# Plate 2 (Gambrel Left)

x2 = @W2x2 - (mpcyy)/(sin(@Phi2))

y2 = @W2y2

m2 = tan(@Phi2)

x1 = @X2

y1 = @Y2

m1 = tan(@Phi1)

x0 = (y2 - y1 - m2*x2 + m1*x1)/(m1 - m2)

y0 = y1 + m1*(x0 - x1)

xoffset = (mpcxx/2.0)*(cos(@Phi2)) + (mpcyy/2.0)*(sin(@Phi2))

yoffset = (mpcxx/2.0)*(sin(@Phi2)) - (mpcyy/2.0)*(cos(@Phi2))

mpcx = x0 + xoffset

mpcy = y0 + yoffset

mpcrot = -@Phi2

MedeekMethods.metal_plate mpcx, mpcy, mpcxx, mpcyy, mpcrot, "PLGL"

# Plate 2 (Gambrel Right)

mpcx = @X5 - mpcx

mpcy = mpcy

mpcrot = @Phi2

MedeekMethods.metal_plate mpcx, mpcy, mpcxx, mpcyy, mpcrot, "PLGR"