I am currently working on the polygon and line tool for both stemwall and slab foundations. I am finding it hard currently to get enough time to really push ahead quickly so I don't have an ETA on the release of these tools.

- Welcome to Medeek Forum.

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

#2191

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 21, 2017, 07:10:42 AM #2192

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 20, 2017, 08:04:56 AM

The ICC codes call out a minimum of a one vent within 3 feet of each corner. It shouldn't be to much trouble to create the openings in the stemwall and place some vents:

For a rectangular building (4 sides) should I place 4 vents or 8 vents? Provide only the openings or also provide a generic foundation vent (lightweight geometry?)

Moving an opening is actually very easy within SketchUp, when it comes to a solid wall like this.

What is the typical header thickness between the top of the vent hole and the top of foundation?

Vent size seems to be 16"x8" for most vents I've seen.

With regards to vents there are the cheap plastic ones you can get a Home Depot or Lowes and and then there are a whole ton of more expensive louvered metal manufacturers of vents and flood vents.

For a rectangular building (4 sides) should I place 4 vents or 8 vents? Provide only the openings or also provide a generic foundation vent (lightweight geometry?)

Moving an opening is actually very easy within SketchUp, when it comes to a solid wall like this.

What is the typical header thickness between the top of the vent hole and the top of foundation?

Vent size seems to be 16"x8" for most vents I've seen.

With regards to vents there are the cheap plastic ones you can get a Home Depot or Lowes and and then there are a whole ton of more expensive louvered metal manufacturers of vents and flood vents.

#2193

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 19, 2017, 10:36:39 PM

I agree, I've been talking to a few other contractors out there and most of them don't pay alot of attention to the orientation of the J-bolts into the concrete, they let the concrete set up a bit and then stab them in.

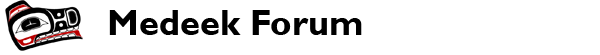

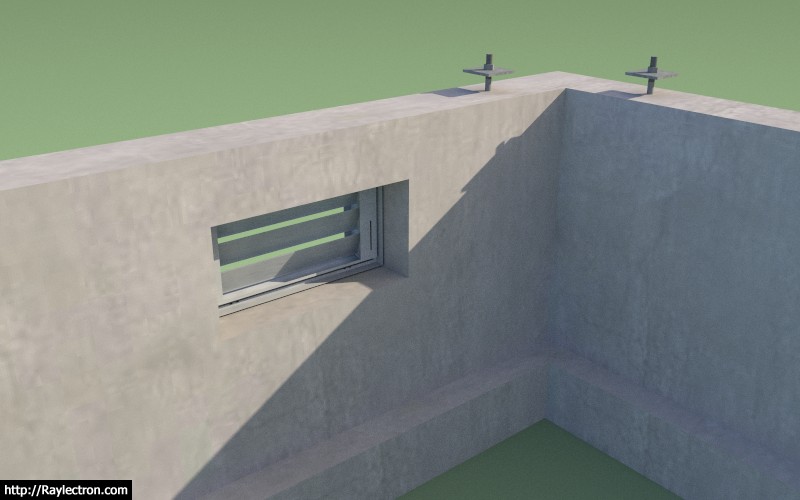

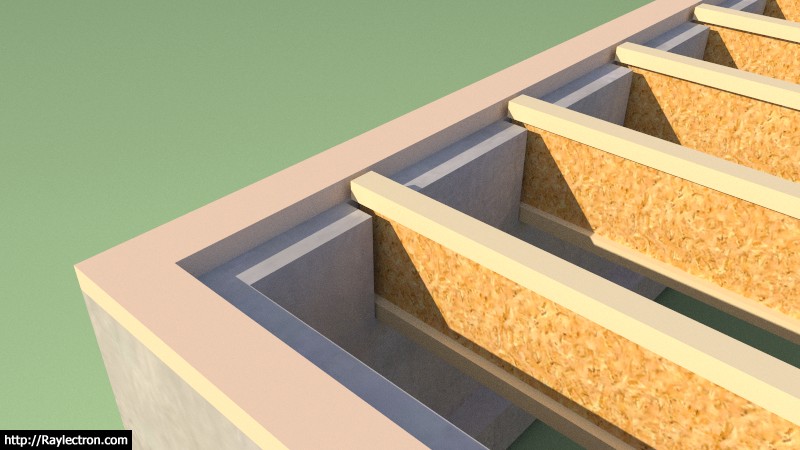

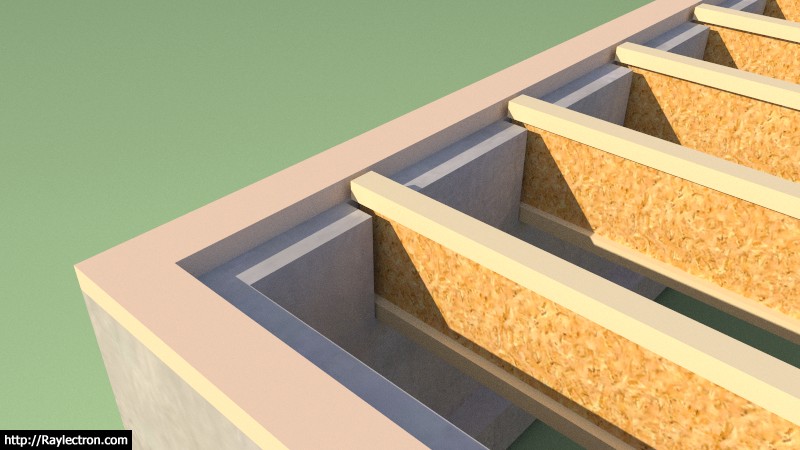

I'm adding in the custom materials, stemwall foundation below is an example:

I will need to roll another revision probably tomorrow to get this update out there.

Any additional thoughts on adding in vents and what is standard construction in your locale as well as what type/brand of foundation vents/inserts are used.

I'm adding in the custom materials, stemwall foundation below is an example:

I will need to roll another revision probably tomorrow to get this update out there.

Any additional thoughts on adding in vents and what is standard construction in your locale as well as what type/brand of foundation vents/inserts are used.

#2194

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 19, 2017, 05:27:07 PM

The cosmetic threads actually render quite nicely as does my rebar material/texture. I just realized I have not added any custom materials into the foundation plugin.

As you can see from the image the orientation of the J-bolts is the same regardless of the wall, however it would not be a couple more lines of code to orient them all facing in or facing out or some other combination. Curious how the contractors actually install these, is the orientation important

As you can see from the image the orientation of the J-bolts is the same regardless of the wall, however it would not be a couple more lines of code to orient them all facing in or facing out or some other combination. Curious how the contractors actually install these, is the orientation important

#2195

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 19, 2017, 01:34:16 AM

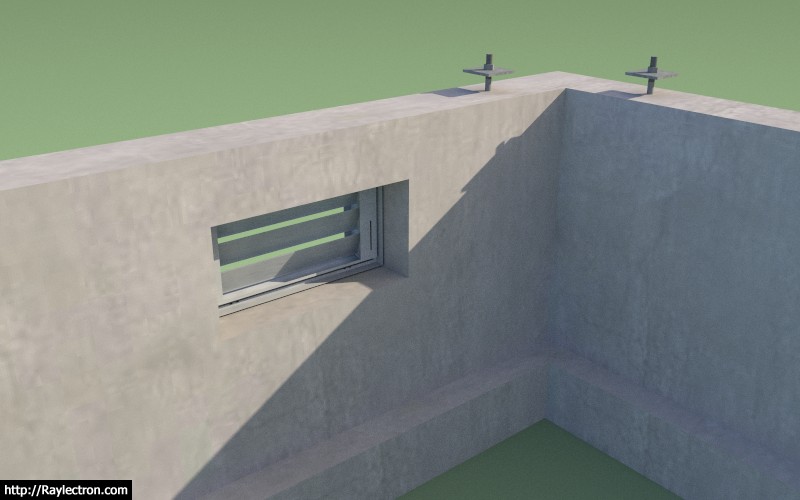

Version 1.0.7 - 03.19.2017

- Added 1/2" and 5/8" Dia. Anchor Bolt option to stemwall and slab on grade foundations.

- Anchor bolt lengths are nominal 10", 12" and 14", square washers are 2"x2" or 3"x3".

View model here:

https://3dwarehouse.sketchup.com/model/d167e6ba-96b1-4211-96df-34b8371d7d5e/Anchor-Bolts-in-Stemwall-Foundation

The anchor bolt, washer and nut are three separate files that are loaded in as components. Then the nut and washer components are inserted inside the bolt component and exploded so only the solid group(s) remain. Its pretty amazing what you can do with a robust API and a little bit of Ruby code.

It took me most of today to figure out how to do all of this since I'm in uncharted territory but now that I've got it kind of figured out it opens up the possibility for a host of other things (holdowns, windows, doors, vents etc...) for this plugin and the others I'm working on.

- Added 1/2" and 5/8" Dia. Anchor Bolt option to stemwall and slab on grade foundations.

- Anchor bolt lengths are nominal 10", 12" and 14", square washers are 2"x2" or 3"x3".

View model here:

https://3dwarehouse.sketchup.com/model/d167e6ba-96b1-4211-96df-34b8371d7d5e/Anchor-Bolts-in-Stemwall-Foundation

The anchor bolt, washer and nut are three separate files that are loaded in as components. Then the nut and washer components are inserted inside the bolt component and exploded so only the solid group(s) remain. Its pretty amazing what you can do with a robust API and a little bit of Ruby code.

It took me most of today to figure out how to do all of this since I'm in uncharted territory but now that I've got it kind of figured out it opens up the possibility for a host of other things (holdowns, windows, doors, vents etc...) for this plugin and the others I'm working on.

#2196

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 18, 2017, 09:41:20 AM

The 1/2" and 5/8" anchor bolts, washers and some standard nuts.

View models here:

https://3dwarehouse.sketchup.com/model/8d99457a-d1a4-488f-bea7-eeddfe8a8b67/Anchor-Bolts

View models here:

https://3dwarehouse.sketchup.com/model/8d99457a-d1a4-488f-bea7-eeddfe8a8b67/Anchor-Bolts

#2197

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 16, 2017, 03:35:22 PM

I need some input from the foundation and truss plugin users. I've decided to pre-model certain things like Bolts, Nuts, Washers etc... With Nuts and Bolts I'm planning on using a cosmetic thread so that the polygon count is minimal. As I've been experimenting with the bolts and nuts I'm wondering if I should eliminate the 30 deg. bevel on the head of the bolt and nut, it looks nice but adds quite a bit of complexity and polygons to the model. Any thoughts on this?

You would sacrifice some realism for a smaller model...

You would sacrifice some realism for a smaller model...

#2198

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 15, 2017, 08:07:01 AM

I'm trying to determine if its easier to write a module that draws the anchor bolts or just bring in the component (pre-drawn). I've never brought in a component before so something I need to explore further. The other thing I feel is key is to make sure any of these minor components are modeled in such as way as to remain fairly lightweight within the model. No one is going to want to use a feature that bogs down their overall model. That is my one big gripe with using the 3D Warehouse models, the polygon count on most models is usually outrageous.

#2199

Medeek Truss Plugin / Re: Development and Updates for the Medeek Truss Plugin

March 13, 2017, 12:07:21 PM

I've been reviewing my Todo list lately and it really hasn't shrunk much, if anything it has grown a bit as I've added some new features in the last month and more catching up needs to be done with various truss types.

I only work on this project part time and on the weekends as much as possible, so my progress since September of 2016 has been quite slow (took a new job with the City of Ocean Shores).

Currently the Truss Plugin has seen the most development but I am also spread between the other separate plugins as well:

Medeek Wall Plugin

Medeek Structural Plugin

Medeek Foundation Plugin

Medeek Deck Plugin

The structural and wall plugins will be just as complex and involved as the Truss Plugin and will require a couple years of my full time attention to get where they need to go.

When I step back and look at everything I want to accomplish there is just no way, given my current situation, that I can achieve it. It would be nice to also be able to hire some help in knocking out some of the coding, realistically there is only so many hours in a day and only so much one person can do.

I would really like to work full time on all of this as I see it has some serious potential and I'm also very excited about it but my previous attempt at using KickStarter to raise some working capital did not amount to much.

I was watching Shark Tank last night and I was thinking would this type of business even have a chance in that setting? Anyhow, I am open to any ideas you might have in how to really blow this thing up and get it going.

I only work on this project part time and on the weekends as much as possible, so my progress since September of 2016 has been quite slow (took a new job with the City of Ocean Shores).

Currently the Truss Plugin has seen the most development but I am also spread between the other separate plugins as well:

Medeek Wall Plugin

Medeek Structural Plugin

Medeek Foundation Plugin

Medeek Deck Plugin

The structural and wall plugins will be just as complex and involved as the Truss Plugin and will require a couple years of my full time attention to get where they need to go.

When I step back and look at everything I want to accomplish there is just no way, given my current situation, that I can achieve it. It would be nice to also be able to hire some help in knocking out some of the coding, realistically there is only so many hours in a day and only so much one person can do.

I would really like to work full time on all of this as I see it has some serious potential and I'm also very excited about it but my previous attempt at using KickStarter to raise some working capital did not amount to much.

I was watching Shark Tank last night and I was thinking would this type of business even have a chance in that setting? Anyhow, I am open to any ideas you might have in how to really blow this thing up and get it going.

#2200

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 12, 2017, 01:07:55 PM

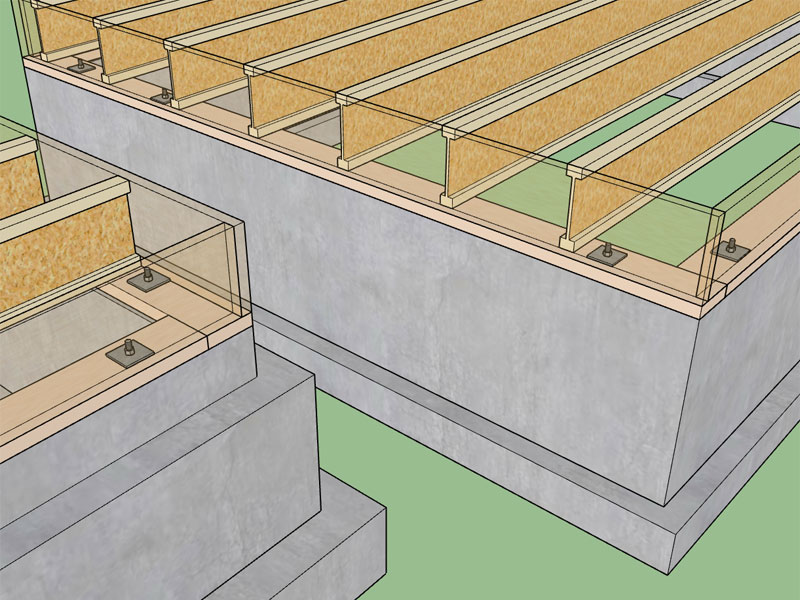

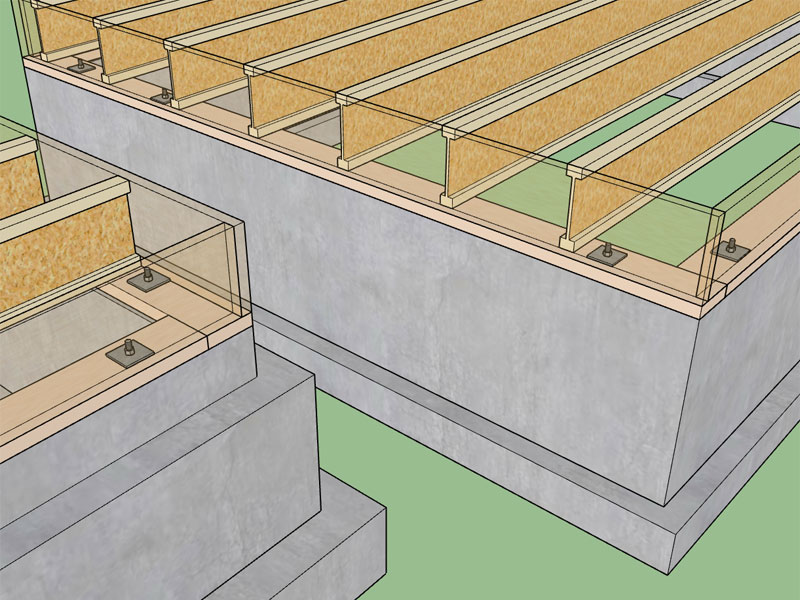

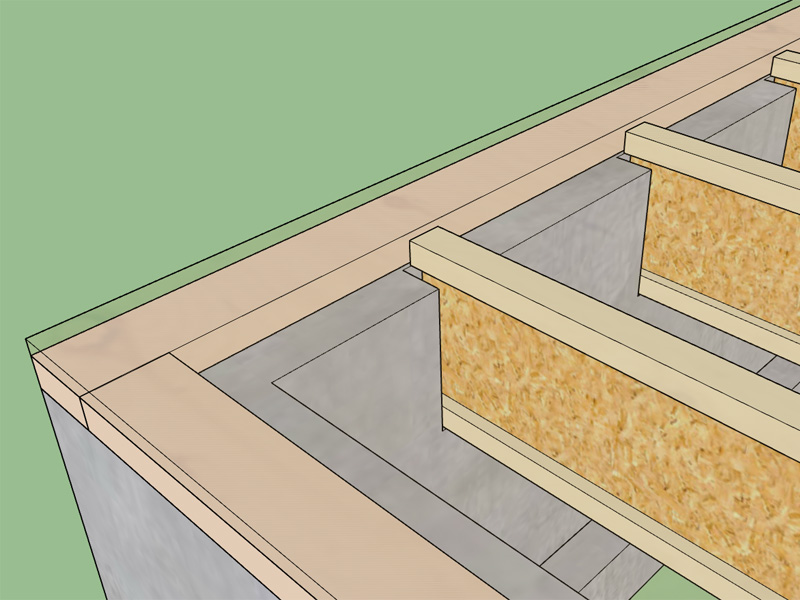

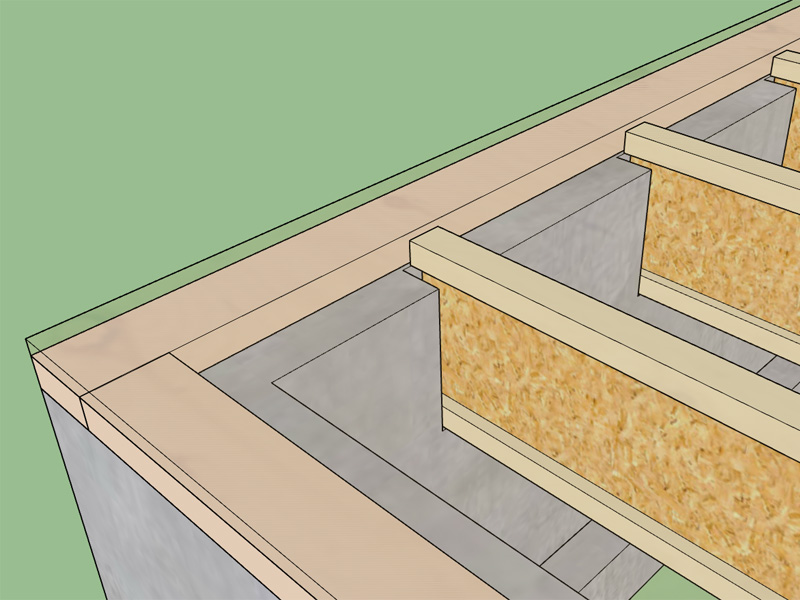

The argument for this construction method is the sheathing height is decreased because the rim board is eliminated. However, in my mind the cons outweigh the pros:

1.) There is a thermal bridge through the stemwall at the corner where the floor meets the wall.

2.) Stemwall construction would become more complicated and time consuming.

3.) Proximity of the I-Joist to the concrete could be problematic, requiring additional measures and more time and effort.

4.) The crawspace height is reduced making it harder for other subs to install and work in and moisture from the ground is more likely to be an issue.

5.) Nut and Washer of anchor bolts protrudes into floor sheathing and bottom wall plate, requiring additional notching.

6.) If you want to run plumbing or electrical down through the wall bottom plate and into the floor, this is nearly impossible with this configuration.

1.) There is a thermal bridge through the stemwall at the corner where the floor meets the wall.

2.) Stemwall construction would become more complicated and time consuming.

3.) Proximity of the I-Joist to the concrete could be problematic, requiring additional measures and more time and effort.

4.) The crawspace height is reduced making it harder for other subs to install and work in and moisture from the ground is more likely to be an issue.

5.) Nut and Washer of anchor bolts protrudes into floor sheathing and bottom wall plate, requiring additional notching.

6.) If you want to run plumbing or electrical down through the wall bottom plate and into the floor, this is nearly impossible with this configuration.

#2201

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 12, 2017, 10:33:28 AM

Or like this?

These two methods seem to be fairly popular in Oregon, I've never seen a floor/stemwall constructed this way any where else.

These two methods seem to be fairly popular in Oregon, I've never seen a floor/stemwall constructed this way any where else.

#2202

Medeek Foundation Plugin / Re: Development and Updates for the Medeek Foundation Plugin

March 09, 2017, 12:20:33 PM

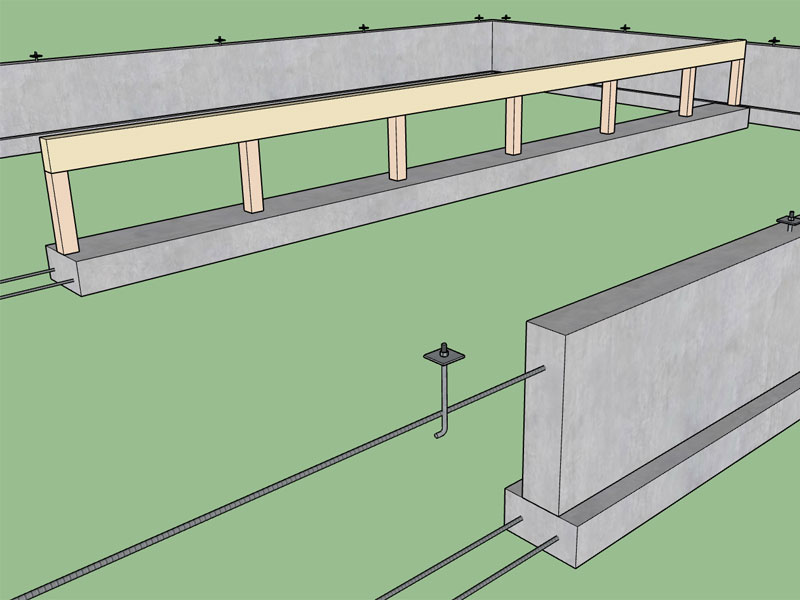

Has anyone ever seen a stemwall framed liked this?

#2203

Medeek Wall Plugin / Re: Development and Updates for the Medeek Wall Plugin

March 06, 2017, 08:14:20 AM

I've thought about using the Profile Builder method of pushing assembly along a path but unfortunately that only works well up to a point. When you start throwing complex openings into the mix things become much more complicated. This plugin may shape up to be even more challenging than the Truss Plugin, I guess will see how far I can take it.

As part of the door openings module there will also be interior vs. exterior as well as garage door openings. The framing aspect of the plugin should also be able to create portal frames with solid sawn and glulam headers.

As part of the door openings module there will also be interior vs. exterior as well as garage door openings. The framing aspect of the plugin should also be able to create portal frames with solid sawn and glulam headers.

#2204

Medeek Wall Plugin / Re: Development and Updates for the Medeek Wall Plugin

March 06, 2017, 07:12:46 AM

This toolbar will be for light frame wood walls. My plan is to have another toolbar (in gray steel blue color) very similar to this one for cold frame steel walls. This will allow for the user to turn on and turn off which ever tools bars they need without having to clutter just one toolbar up with too many options that may or may not apply to that wall type. Similarly a separate toolbar for CMU walls as I get to that.

I'm sure there are other wall types that will come up but initially I plan on focusing on the standard wool wall and perfecting that as much as possible.

Things will get complicated with the cladding options (ie. siding, brick facade, cultured stone, stucco and river rock) especially where they are partial wall heights and other interesting features like trim, corner treatments (Quoin), lintels, keystones and arched window and doorways. Even the typical siding products like hardi-plank will have a number of cladding and trim options.

Here is a typical oval window that the plugin should be able to generate:

The there is the interior details (trim) of windows and doors that also should be provided by the plugin as an option:

Most houses I've lived in had only had the GWB surrounding the windows but at the minimum the doors usually has some form of casing or surround. Integral to this is the baseboard and the optional crown molding and wainscoting.

I'm sure there are other wall types that will come up but initially I plan on focusing on the standard wool wall and perfecting that as much as possible.

Things will get complicated with the cladding options (ie. siding, brick facade, cultured stone, stucco and river rock) especially where they are partial wall heights and other interesting features like trim, corner treatments (Quoin), lintels, keystones and arched window and doorways. Even the typical siding products like hardi-plank will have a number of cladding and trim options.

Here is a typical oval window that the plugin should be able to generate:

The there is the interior details (trim) of windows and doors that also should be provided by the plugin as an option:

Most houses I've lived in had only had the GWB surrounding the windows but at the minimum the doors usually has some form of casing or surround. Integral to this is the baseboard and the optional crown molding and wainscoting.

#2205

Medeek Wall Plugin / Re: Development and Updates for the Medeek Wall Plugin

March 05, 2017, 10:44:34 PM

The initial toolbar:

I may add a couple more icons for editing and deleting openings (windows,doors).

I may add a couple more icons for editing and deleting openings (windows,doors).