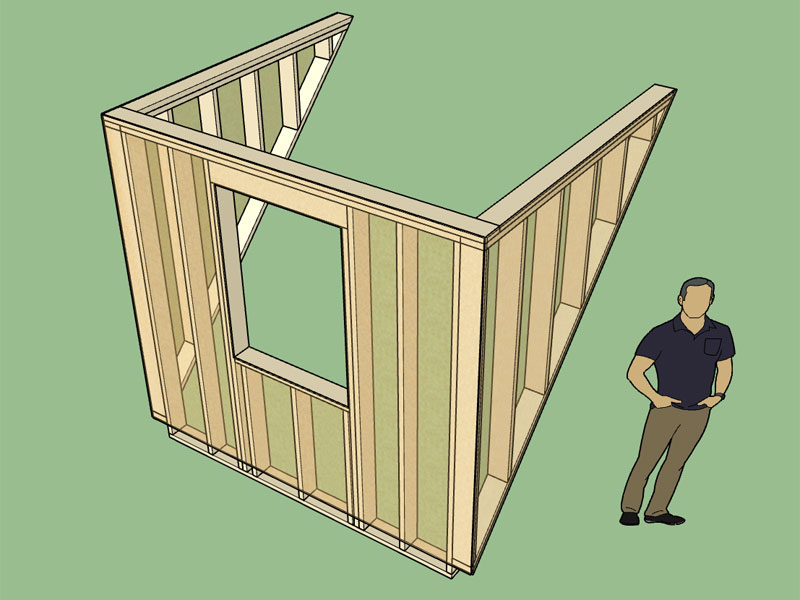

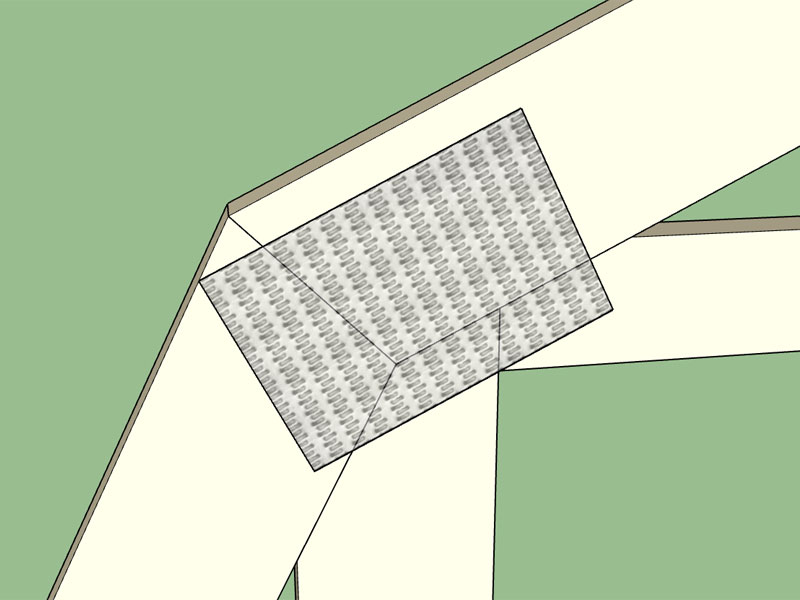

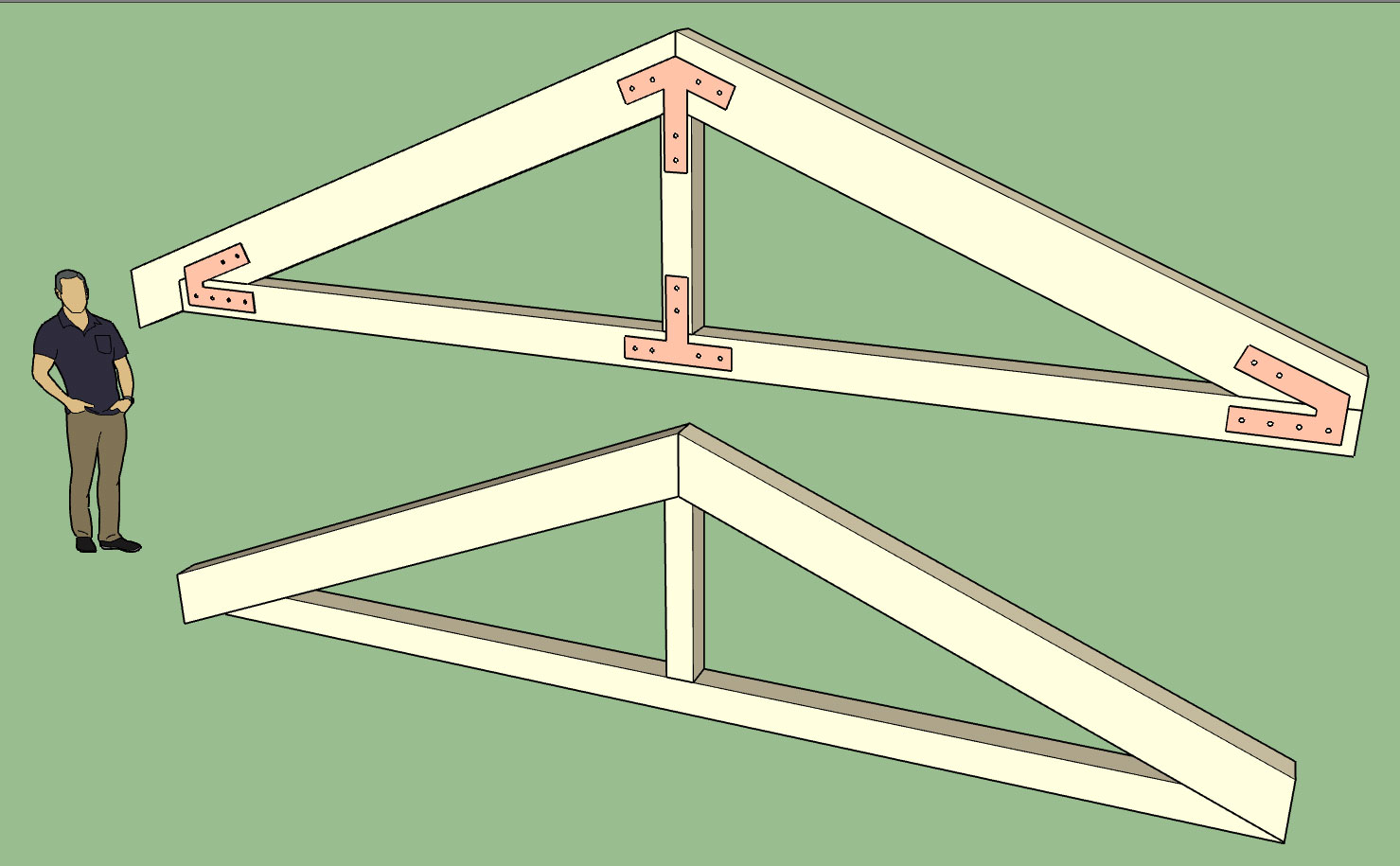

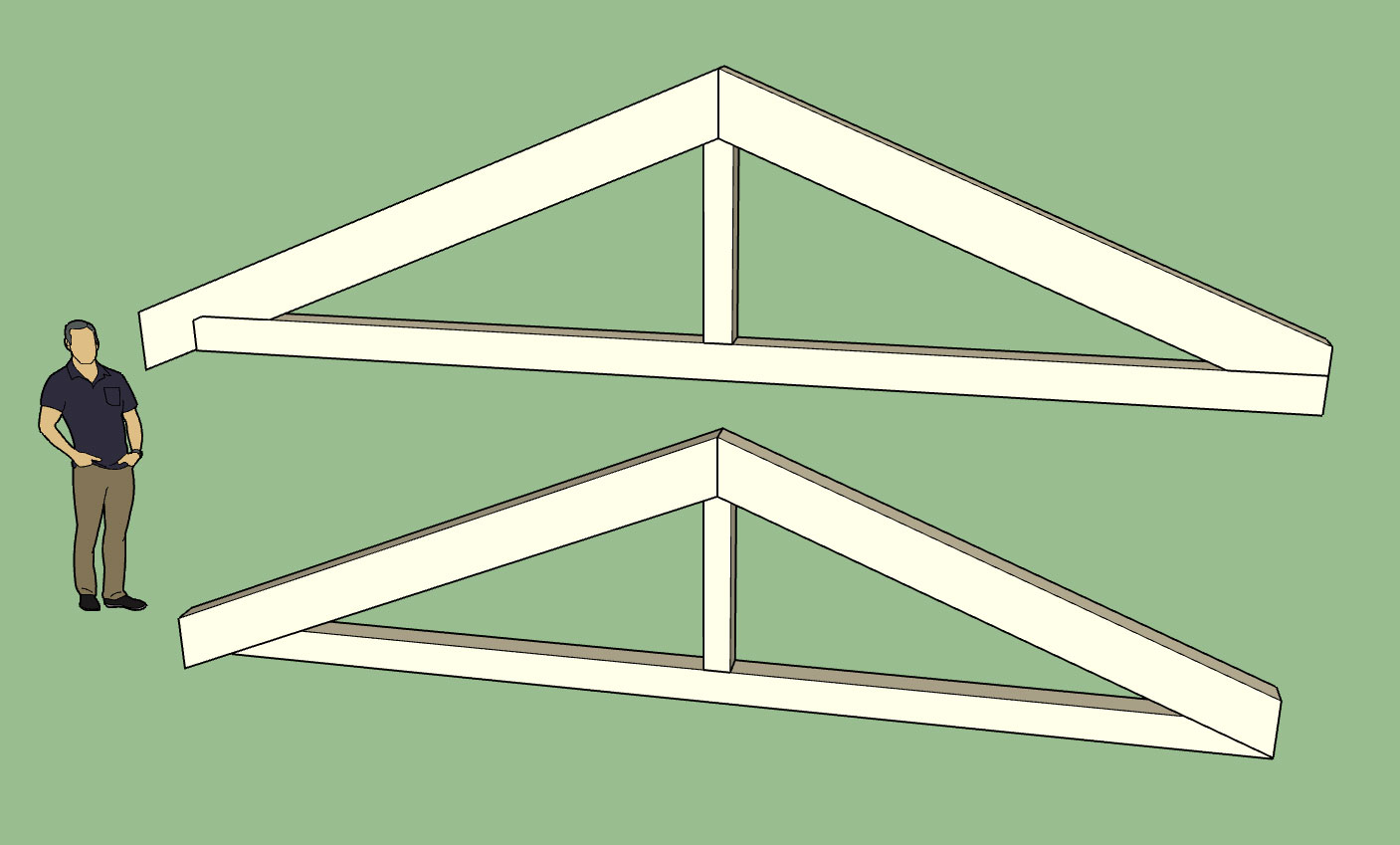

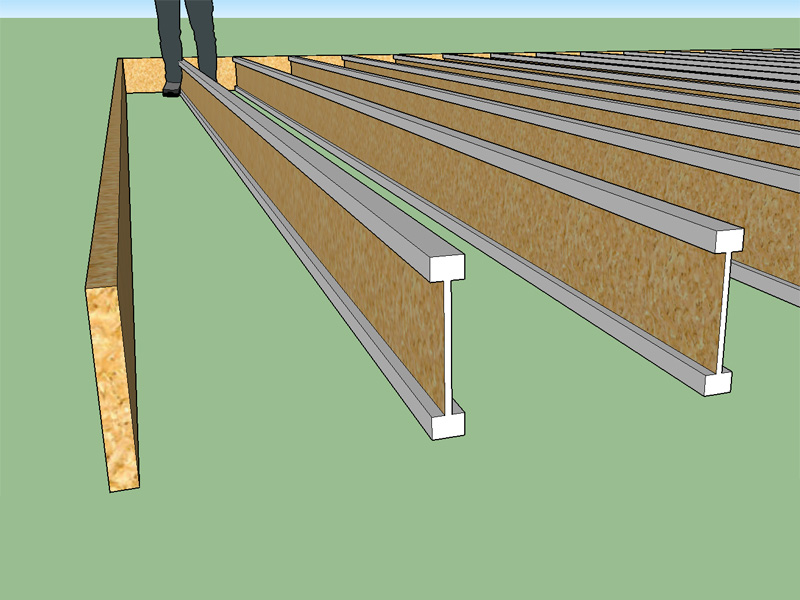

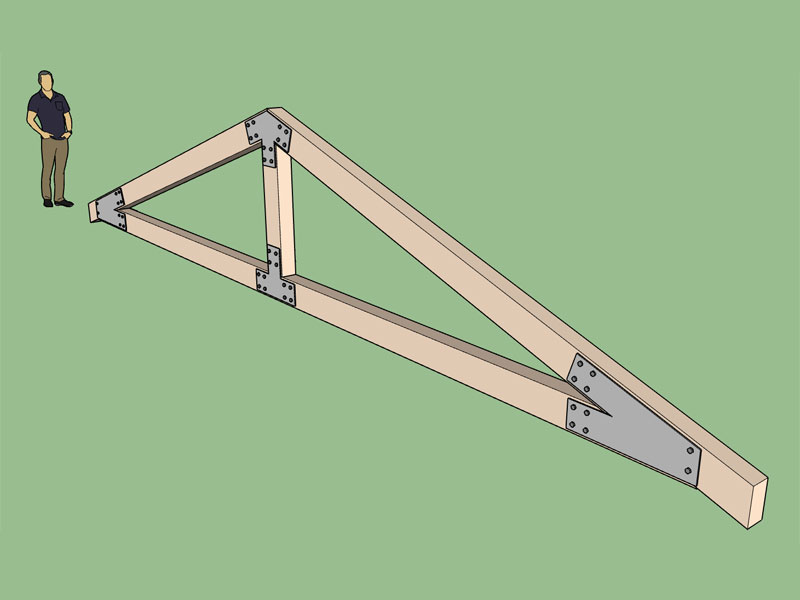

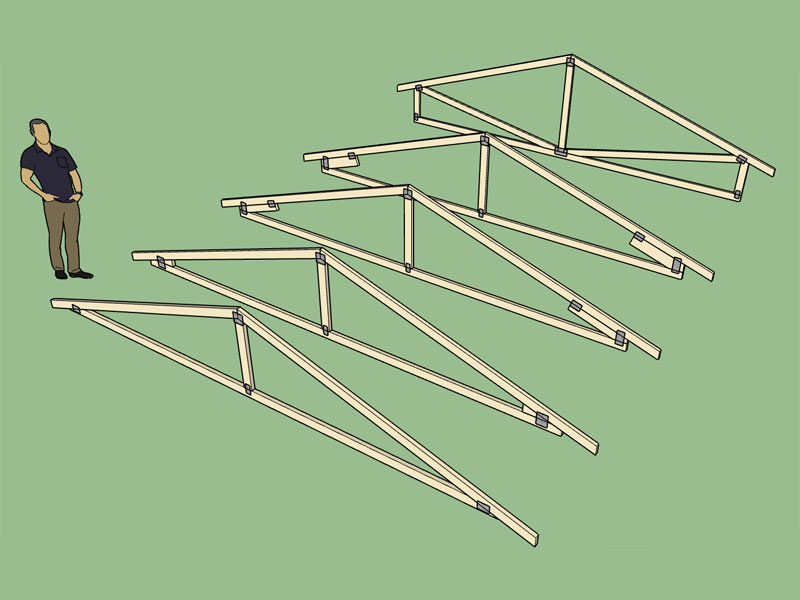

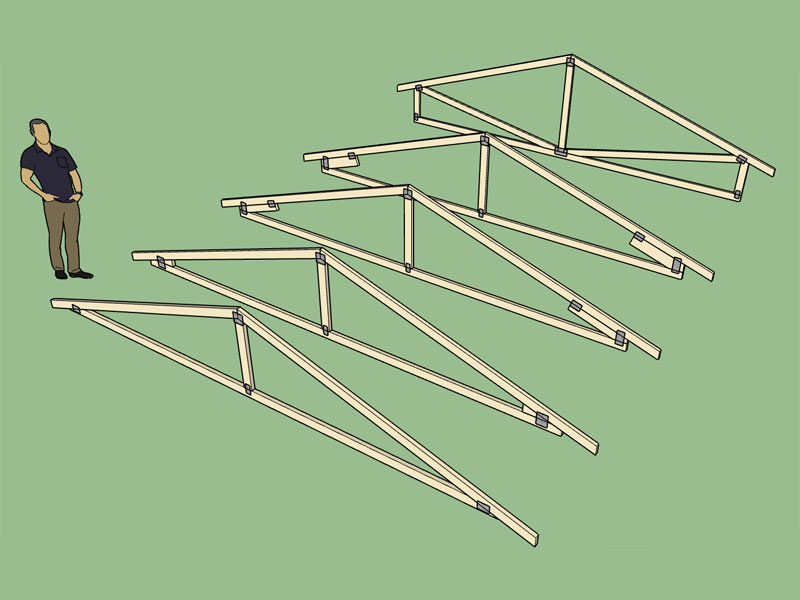

Raised/Energy heels add another level of complexity to the equation. Below you can see that various heights of a raised heel on a simple King Post truss requires different configurations and hence separate plating routines:

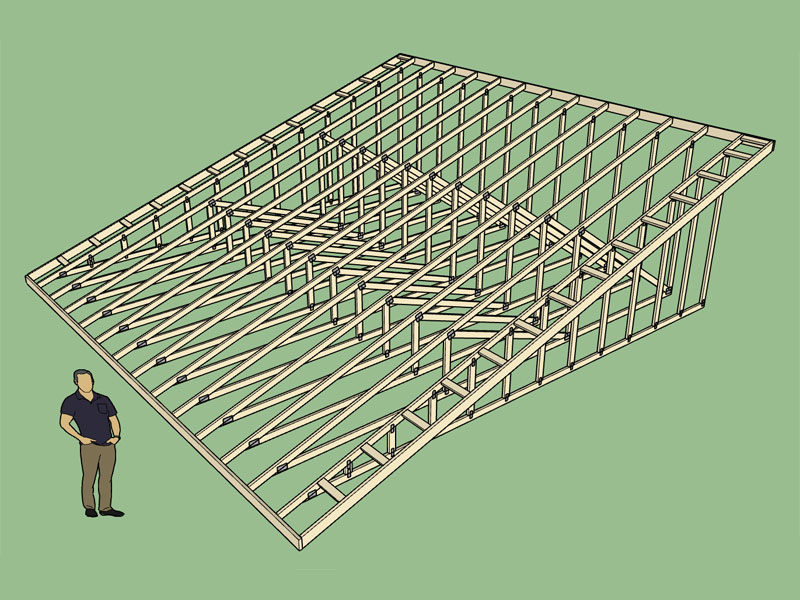

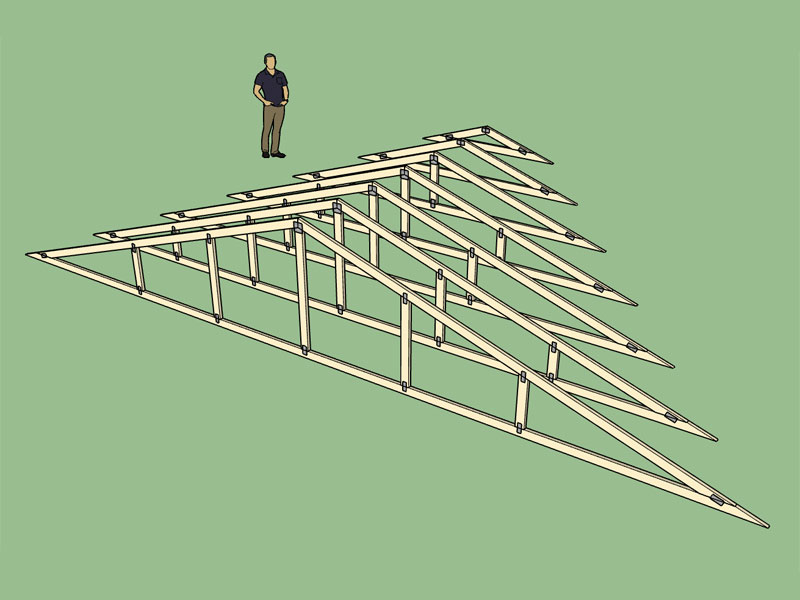

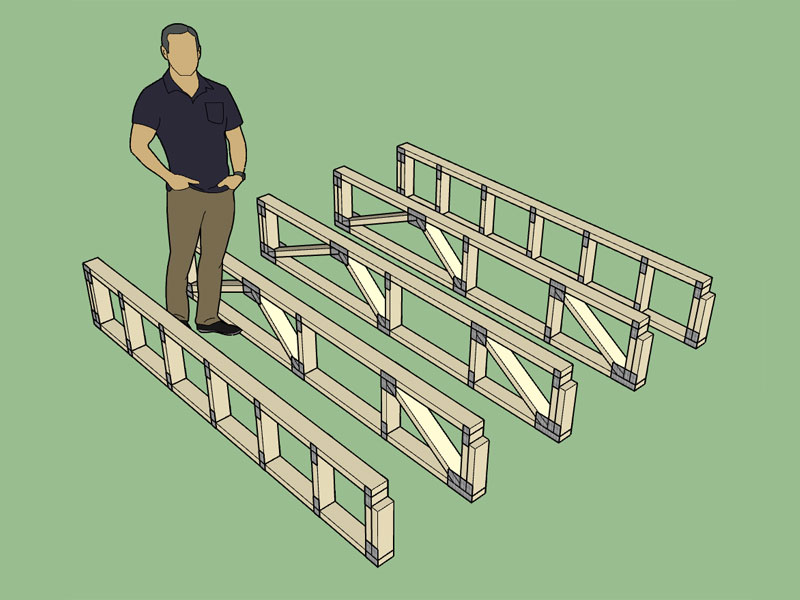

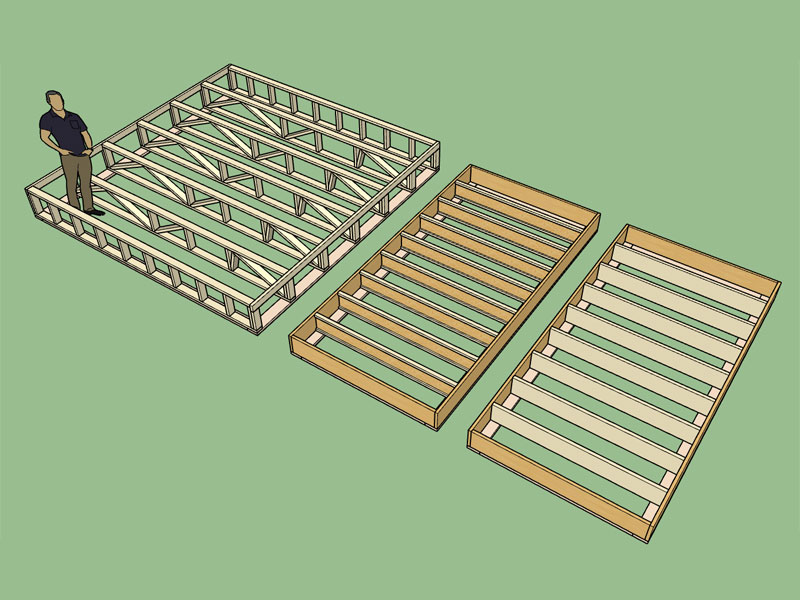

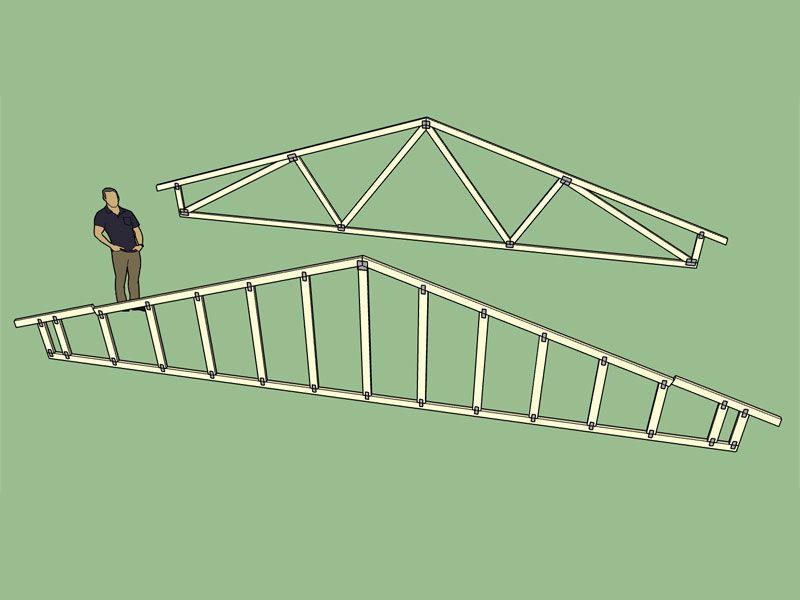

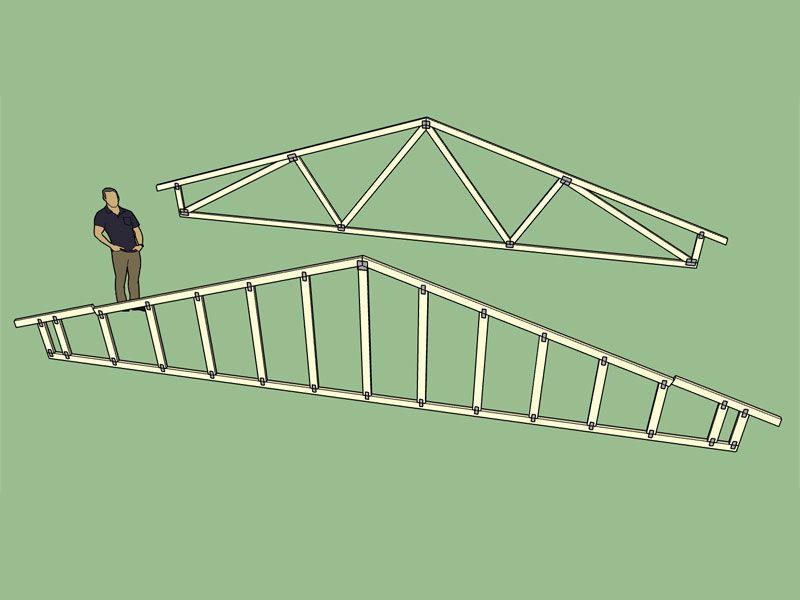

This also affects the gable trusses as well, below is a fink truss with its gable counterpart:

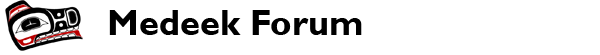

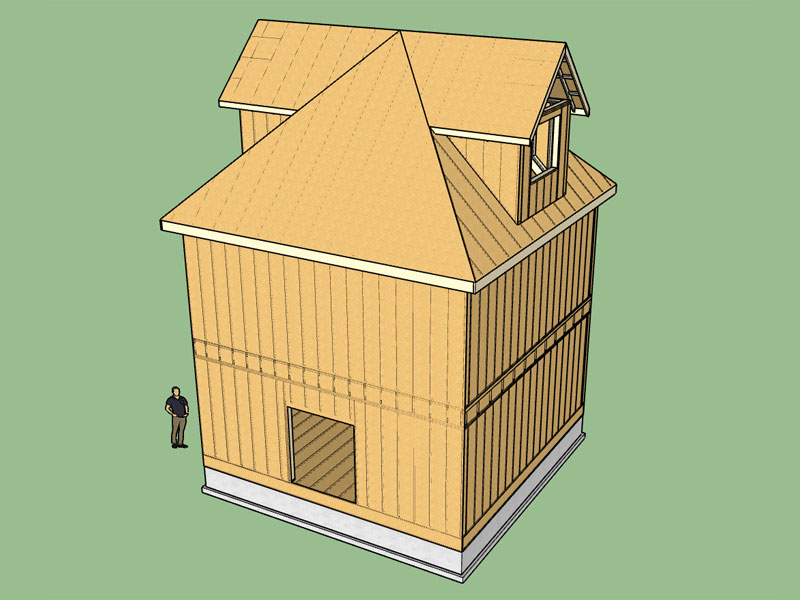

View models here:

https://3dwarehouse.sketchup.com/model.html?id=91d8d78a-8e6c-4dab-9839-4d689c84c297

https://3dwarehouse.sketchup.com/model.html?id=89739563-049f-4277-bfca-75663724967e

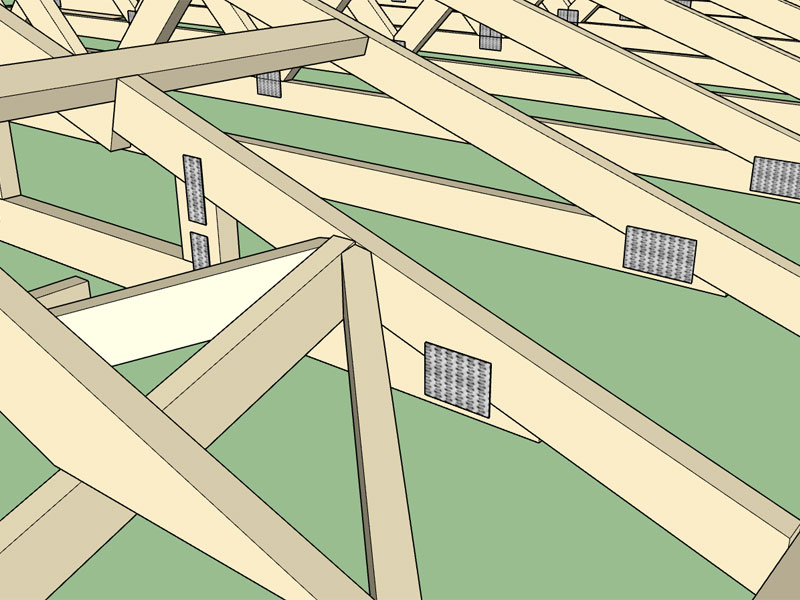

I'm still house cleaning. I've now got the King Post and Fink truss fully cleaned up with connector plates enabled for all possible configurations (raised heel, non-raised heel, structural, non-structural). I've only got 10 more common truss types to work through, see list below:

Queen Post

Howe

Fan

Mod Queen

Double Fink

Double Howe

Mod Fan

Triple Fink

Triple Howe

Quad Fink

This also affects the gable trusses as well, below is a fink truss with its gable counterpart:

View models here:

https://3dwarehouse.sketchup.com/model.html?id=91d8d78a-8e6c-4dab-9839-4d689c84c297

https://3dwarehouse.sketchup.com/model.html?id=89739563-049f-4277-bfca-75663724967e

I'm still house cleaning. I've now got the King Post and Fink truss fully cleaned up with connector plates enabled for all possible configurations (raised heel, non-raised heel, structural, non-structural). I've only got 10 more common truss types to work through, see list below:

Queen Post

Howe

Fan

Mod Queen

Double Fink

Double Howe

Mod Fan

Triple Fink

Triple Howe

Quad Fink