3'x8' Rabbit Hutch - Copalis Beach, WA - 2013

For my twins birthday I decided to get them a pair of rabbits, which quickly became 5 rabbits, one for each kid. Now we needed somewhere to house them. After doing a little research online and looking at different commercially available rabbit cages I decided the rabbits would be much more comfortable in a larger cage with some place to stretch their legs a bit and graze. I then came up with planset RH3080 which allows for both and also lets one move the cage every day to fresh spot on the lawn, fertilizing the grass and mowing it in the process.

Day 1

Grabbed some lumber at the Home Depot while I was in town (Aberdeen) and purchased the cage wire from a couple of feed stores in Montesano. I couldn't find the 1/2"x1" 14 GA floor wire for the house portion so I had to settle for 16 GA wire.

I decided to use pressure treated lumber for the all the 2x2's that contacted the ground. The wood wanted to split so I pre-drilled the holes for the 3" deck screws that connected the runners to the floor joists.

With the holes pre-drilled the assembly went together without a hitch, no splitting and everything lined up nicely.

Enlisted the help of my oldest son (Jared) in hopes that he might learn some construction.

The floor assembly was the simple part, cutting and attaching the rafters was a slightly different story.

While I cut the rafters I had Jared layout the ridgeboard with his new speed square and carpenter pencil I bought him for Christmas. For being only nine years old he did a surprisingly accurate job of it.

What made cutting the rafters difficult was the 53 degree angle, my miter saw could only get to about 51 degrees so I had to improvise slightly but after a few test pieces it all worked out.

Attaching them to the ridge board and runners though proved to be a real pain. I pre-drilled all the screw holes but it seemed like everything wanted to split. After a few failures and some liberal use of wood glue and liquid nails it finally came together, by then it was dark out and getting late.

Next I layed out the wall panels, jig sawed them out and attached them with 1-5/8" deck screws. I used deck screws instead of nails for most structural components because the rabbit hutch was designed to be moved around alot and I didn't need nails working loose over time.

I should have attached the floor wire/mesh prior to attaching the rafters to the runners. Instead I ended up building a separate frame with the floor wire attached that inserted into the opening in the floor of the house. This method involved more labor and materials but it also makes the floor removable and replaceable in the future. Plywood for the walls and roof is also a much better choice than OSB, especially in wet climates.

Next I attached the roof panels making sure I had the proper overhang on all edges and also checking for square.

With the roof panels attached all of the major framing was done then it was on to the roof and hardware.

First though Edmond our youngest had to come out and inspect the structural integrity of the structure. We passed inspection with flying colors.

I had some 15# roofing felt leftover from the last construction project. That went on first with some staples and asphalt roofing cement.

Next came the rolled roofing, which I simply rolled over the top and attached with some 1-1/2" roofing tacks and some more of the roofing cement. Cutting the rolled roofing was troublesome, it seemed to want to tear more than cut using a standard hooked blade. Eventually I gave up on trying to cut it with a razor and used a large pair of shears, which by the end were completely ruined.

Along all the edges I ran a bead of the roofing cement to keep out the moisture and also to keep the edges from peeling up in the windstorms we get during the winter. This little roof isn't going anywhere. I also covered all of the tacks over with roofing cement to seal everything up nicely.

Edmond and I cut out the door frame and assembled it. I originally planned for corner braces only on the backside but after I put it all together I realized that this was inadequate so I added some 3/8" Plywood triangles on the front, however on the plans I will specify corner braces front and back since they provide a cleaner look.

Checked that the door fit correctly, a bit tight so I shaved the edges and corners with the knife and then attached the hinges and latch.

Next we attached the hinges and latch to the house door and also I added a 5" rabbit feeder to the backside of the door.

By then it was nearly 2 A.M. in the morning so we decided to call it a night and try again the next morning.

Day 2

Day 2 started with figuring out how best to orient the wire and attach it to the wood. I was going to use my regular T-50 stapler but after a bit of research I found the T-25 staples (9/16") with a round crown so we went with those instead.

We attached the carry handle on the side after we had stapled the wire down otherwise we would have had to cut the wire around the handle.

I first stapled the cage wire in place and then bent or cut it to fit. A good pair of hefty wire cutters is recommended for 14 GA wire unless you have strong hands.

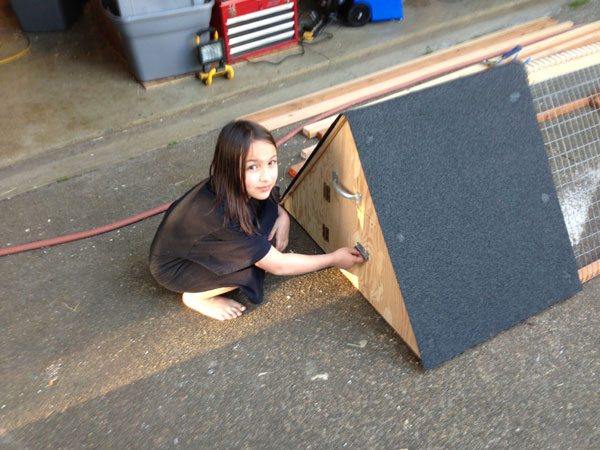

Miriam (my oldest daughter) took a break from Minecraft to come out and inspect our workmanship.

As I mentioned above I forgot to put the floor wire in during the early framing process. If you look closely you can see that I added a separate 2x2 frame (pressure treated) with the floor cage wire attached. Before I installed it I spray painted it a couple times to help prevent it becoming saturated with rabbit urine. The placement of the feeder on the inside of the door is a great way to keep the feed dry and out of the rain and also make it very accessible.

The kids were really excited to see their rabbits go into their new home. Samuel and Edmond are checking out all the new features.

I painted the entire rabbit hutch with a red primer paint since I had a few extra spray cans laying around. I highly recommend either painting or staining the wood especially in damp climates. My previous experience with leaving untreated wood (dog house in the background) has not been good, in a matter of a few days black mold will already be visibly discoloring the wood. With a good coat of paint the rabbit hutch will last much longer and provide a few good years of service.

I added a wire hay rack I constructed out of the 1"x2" cage wire, I should have taken a better picture before I loaded it up with the Timothy hay. We also added three water bottles and an additional 7" feeder for good measure. I was worried with 5 rabbits in this hutch that they might be overcrowded but so far it does not seem to be the case.

My favorite thing about this hutch is the ability to move it around daily. Eliminates having to clean up their droppings since it is already distributed on the lawn doing its job.

The rabbits are loving their new home, they graze all day and run around quite a bit.

UPDATE Fast forward to summer of 2015... Rabbits have long since moved on and now our three guinea pigs are enjoying their new home. The paint was beginning to show some wear so I gave the hutch a fresh coat of paint a few days after I snapped this photo. The entire structure is holding up magnificently with no signs of rot or other issues. We move the guinea pigs every morning since they mow down their patch of lawn rather quickly.

This simple plan can be downloaded in PDF format or purchased as a paper copy here: RH3080.

If you have any questions about the steps involved in this build or planset please contact us.